In November 2016, the EN388 standard was updated to offer more consistent testing and as a result of the development of numerous new materials.

This piece of legislation provides information about the mechanical resistance of safety gloves, based on abrasion, cut, tear and puncture resistance. It also tests impact protection.

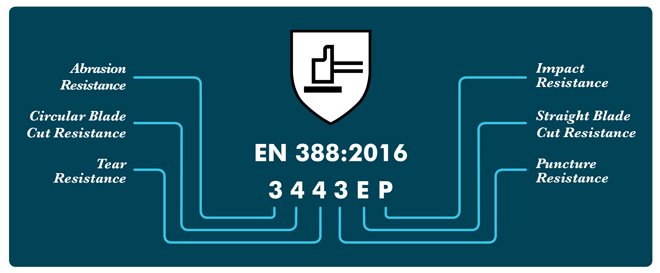

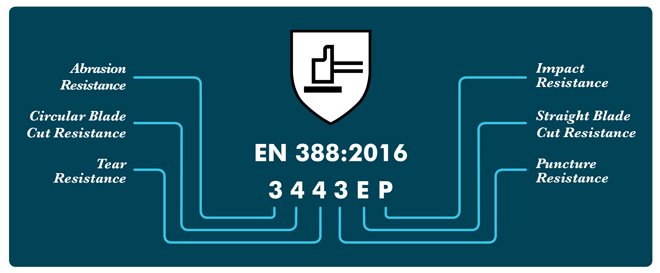

It is easy to spot gloves that conform to the EN 388 standard, as they will be marked with a shield up to six (was previously four) figures will be featured underneath the shield, which denote the level of protection that particular product will offer according to EN 388.

Note: the higher the number, the better the protection. If a glove was not tested for a certain category, it may be marked with an ‘x’ instead.

"This piece of legislation provides information about the mechanical resistance of safety gloves, based on abrasion, cut, tear and puncture resistance. It also tests impact protection."

How to read the markings

EN388:2016 provides us information as above: Abrasion Resistance, Circular Blade Cut Resistance, Tear Resistance, Impact Resistance, Straight Blade Cut Resistance & Puncture Resistance.

Abrasion Resistance: Rated from 1 - 4 - How well do the gloves resist abrasion? If you’re handling bricks, rocks and rough materials, you’ll want this number to be high. Most of our gloves have high abrasion resistance, even the

PG101, one of our lightest gloves.

Coupe Test Cut Resistance: Since the latest revision, straight blade cut resistance has also been added, which we will talk about below. Ranging from 1 - 5, the higher the greater the cut resistance! Our

PG510 dual-layer nitrile gloves have a great cut-resistance with a rating of 4.

Tear Resistance: Ranging between 1 - 4. If you’re looking for a durable glove for use in demanding environments, check out this number! Our

PG330 features high breathability & dexterity with a tear resistance of 4!

Puncture Resistance

Puncture Resistance: Again, ranging from 1-4, essential to consider if you’re working with the likes of needles, syringes and any waste-work. The

PG510 offering level 4 puncture resistance, is a perfect choice.

TDM-100 Cut Resistance: As discussed overleaf, this updated cut resistance test offers a more ‘realworld’ analysis of a glove’s resistant to sharp edges. The new test is rated from A to F (with F offering the most protection). An X may also be listed in the 5th position if a glove has not been tested for a cut rating.

There could also be an ‘X’ – this means that the glove has not been tested for this hazard.

The Pawā®

PG520 has an ISO cut level E while the

PG550 achieves the highest rating, level F.

Impact Resistance: Typically, one to check for if you’re working with heavy objects or there’s a risk of your hands being trapped. This is currently an optional test. There’s only one rating for this – P – this means the glove has passed the test.

It’s essential that you audit your tasks and hazards before purchasing your next pair of safety gloves. By assessing, you can protect yourself and your team. Browse our range of

safety gloves and feel free to

contact us for any advice or queries.

Puncture Resistance: Again, ranging from 1-4, essential to consider if you’re working with the likes of needles, syringes and any waste-work. The PG510 offering level 4 puncture resistance, is a perfect choice.

TDM-100 Cut Resistance: As discussed overleaf, this updated cut resistance test offers a more ‘realworld’ analysis of a glove’s resistant to sharp edges. The new test is rated from A to F (with F offering the most protection). An X may also be listed in the 5th position if a glove has not been tested for a cut rating.

There could also be an ‘X’ – this means that the glove has not been tested for this hazard.

The Pawā® PG520 has an ISO cut level E while the PG550 achieves the highest rating, level F.

Impact Resistance: Typically, one to check for if you’re working with heavy objects or there’s a risk of your hands being trapped. This is currently an optional test. There’s only one rating for this – P – this means the glove has passed the test.

It’s essential that you audit your tasks and hazards before purchasing your next pair of safety gloves. By assessing, you can protect yourself and your team. Browse our range of safety gloves and feel free to contact us for any advice or queries.

Puncture Resistance: Again, ranging from 1-4, essential to consider if you’re working with the likes of needles, syringes and any waste-work. The PG510 offering level 4 puncture resistance, is a perfect choice.

TDM-100 Cut Resistance: As discussed overleaf, this updated cut resistance test offers a more ‘realworld’ analysis of a glove’s resistant to sharp edges. The new test is rated from A to F (with F offering the most protection). An X may also be listed in the 5th position if a glove has not been tested for a cut rating.

There could also be an ‘X’ – this means that the glove has not been tested for this hazard.

The Pawā® PG520 has an ISO cut level E while the PG550 achieves the highest rating, level F.

Impact Resistance: Typically, one to check for if you’re working with heavy objects or there’s a risk of your hands being trapped. This is currently an optional test. There’s only one rating for this – P – this means the glove has passed the test.

It’s essential that you audit your tasks and hazards before purchasing your next pair of safety gloves. By assessing, you can protect yourself and your team. Browse our range of safety gloves and feel free to contact us for any advice or queries.